What is Honing?

Honing Process | Multi Pass Honing | Single Pass Honing

Honing is an abrasive machining process that imparts precision surface to a work-piece, generally meaning the process of finishing of holes with precision geometric form and surface finish.

Although there is the terminology of Flat Surface Honing (which we shall ignore for the purpose of this article), in general Honing refers to finishing holes in terms of final sizing and creating desired surface finish pattern on the interior surface of holes in a work-piece.

‘Final sizing’ refers to producing holes with precision geometric form i.e., controlled diameter, circularity & cylindricity.

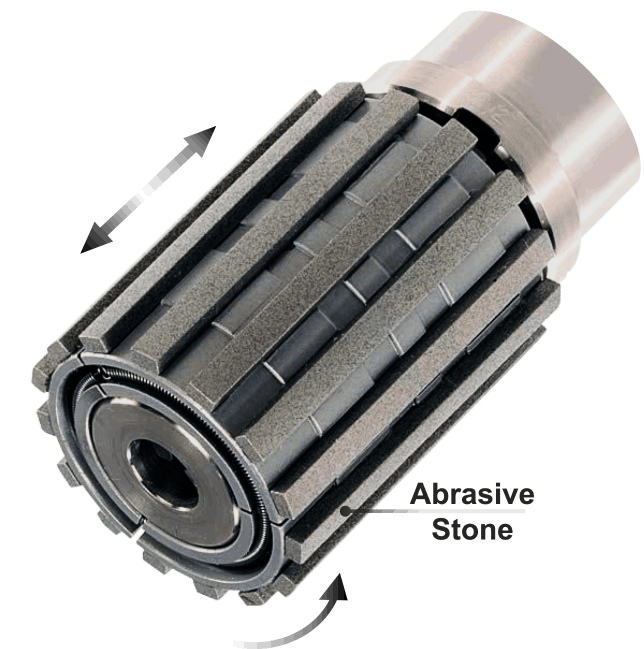

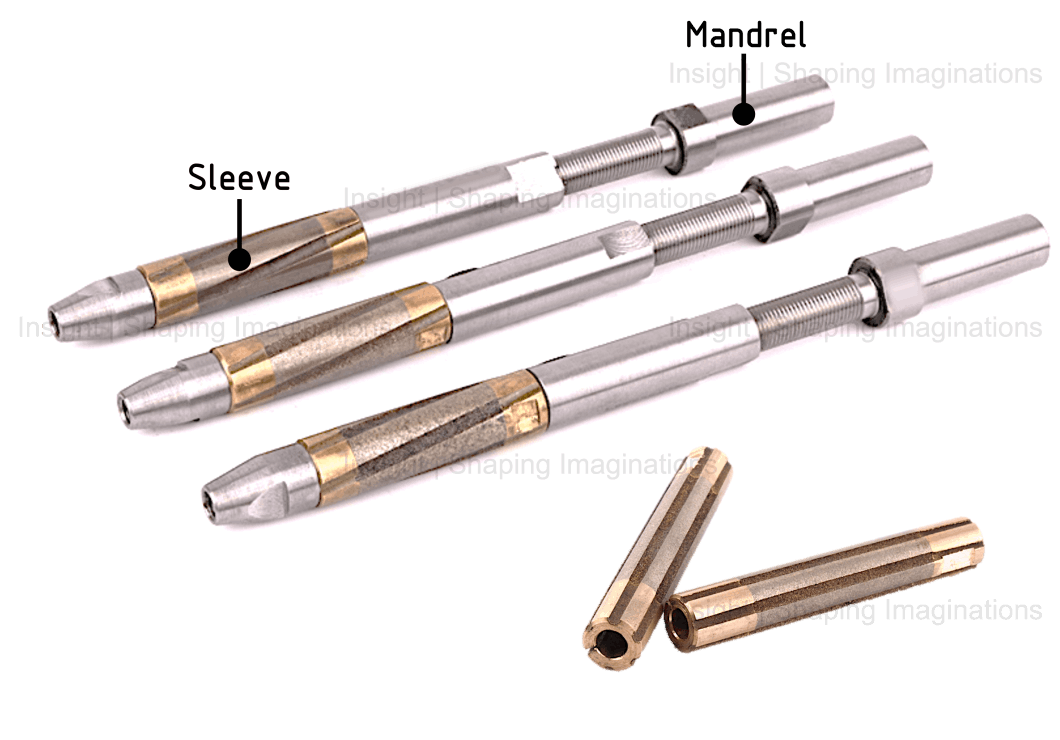

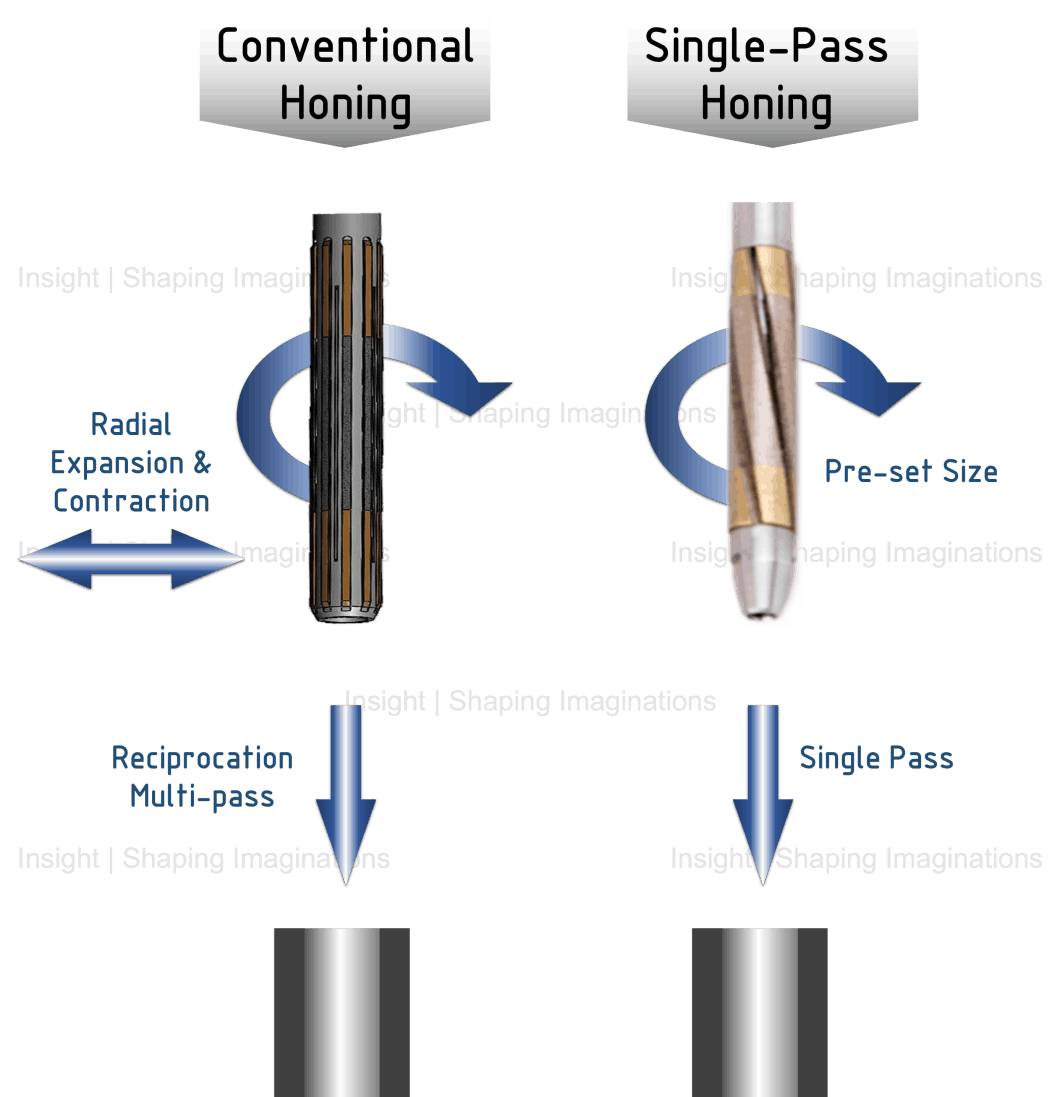

‘Machining’ process takes place by the mechanism of abrasive scrubbing & micro-grooving – accomplished by a tool that radially expands abrasive stones striped to it.

Grit size & grade of the abrasive stones influence the level of form control and surface roughness generated. The tool (more aptly the abrasive stones) are rotated and reciprocated in the work-piece (hole) with controlled radial-expansion pressure given to the stones.

This combined motion (rotation & reciprocation) generates a cross-hatch pattern on the interior surface of the work-piece.

Input hole size of the work-piece is generally pre-machined by way of boring or reaming, to achieve a certain level of consistency in amount of material removed and to enhance honing tool life.

From the point of view of precision manufacturing, in-depth comprehension of quality requirements of the work-pieces, core principles of surface structure formation, and right applications of honing - enable sustainable manufacturing of high-quality finished products in industries like automotive, aerospace, medical, and so many others. By effectively leveraging the schematics, capabilities & benefits of honing, manufacturers can produce precise and efficient components & products - that meet the demands of modern engineering.